Sheet Pile

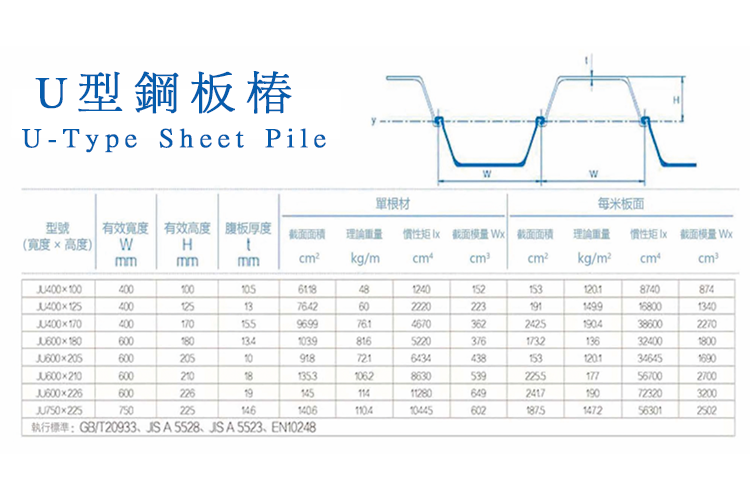

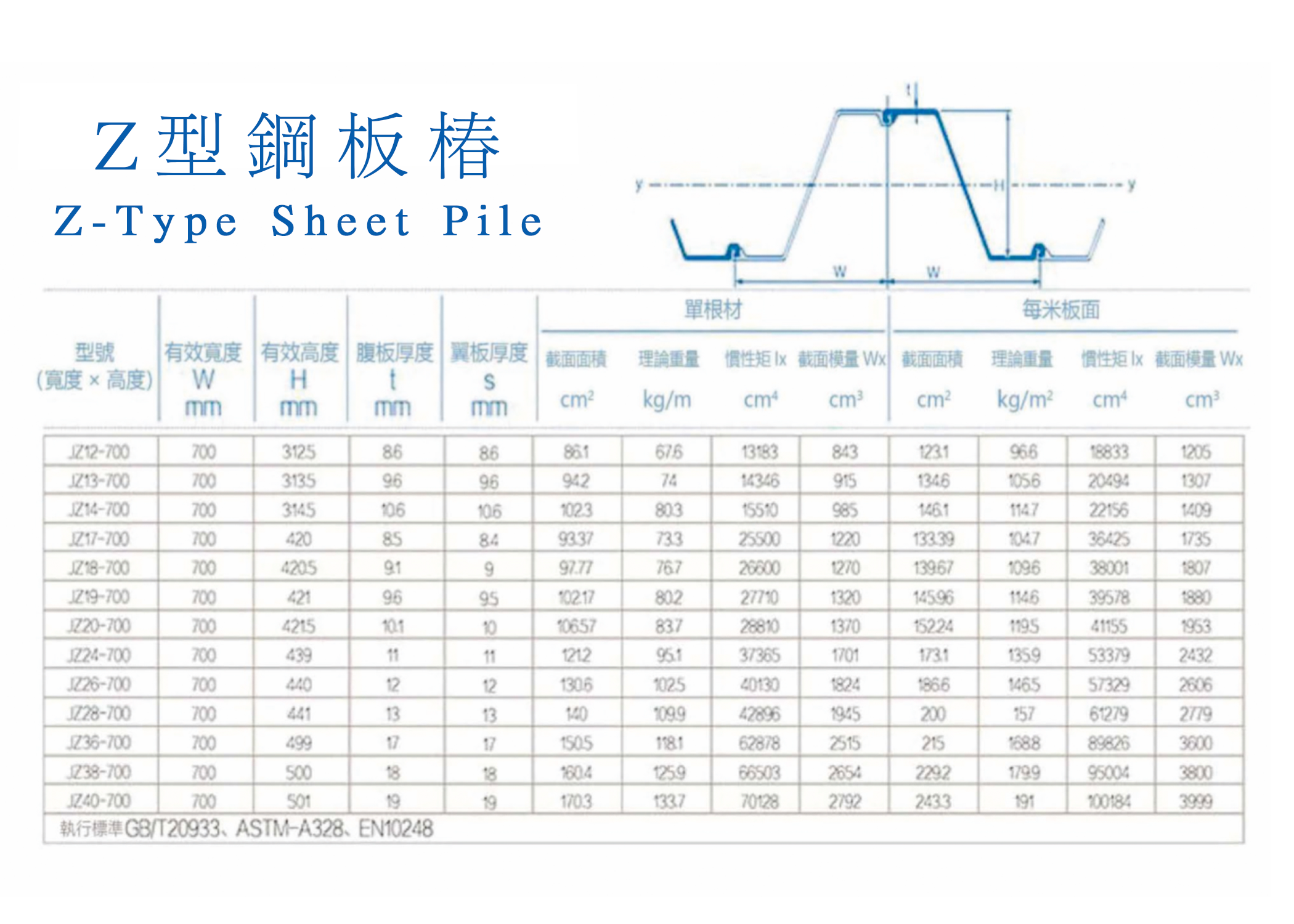

Steel sheet piles are a type of steel with interlocking edges. Their cross-sections come in various shapes such as flat, U-shaped, and Z-shaped, and they are available in different sizes and interlocking forms. Based on the manufacturing process, they can be divided into hot-rolled steel sheet piles and cold-formed thin-walled steel sheet piles. According to their shapes, they can be further classified into U-shaped steel sheet piles, H-shaped steel sheet piles, L-shaped steel sheet piles, S-shaped steel sheet piles, and straight steel sheet piles.

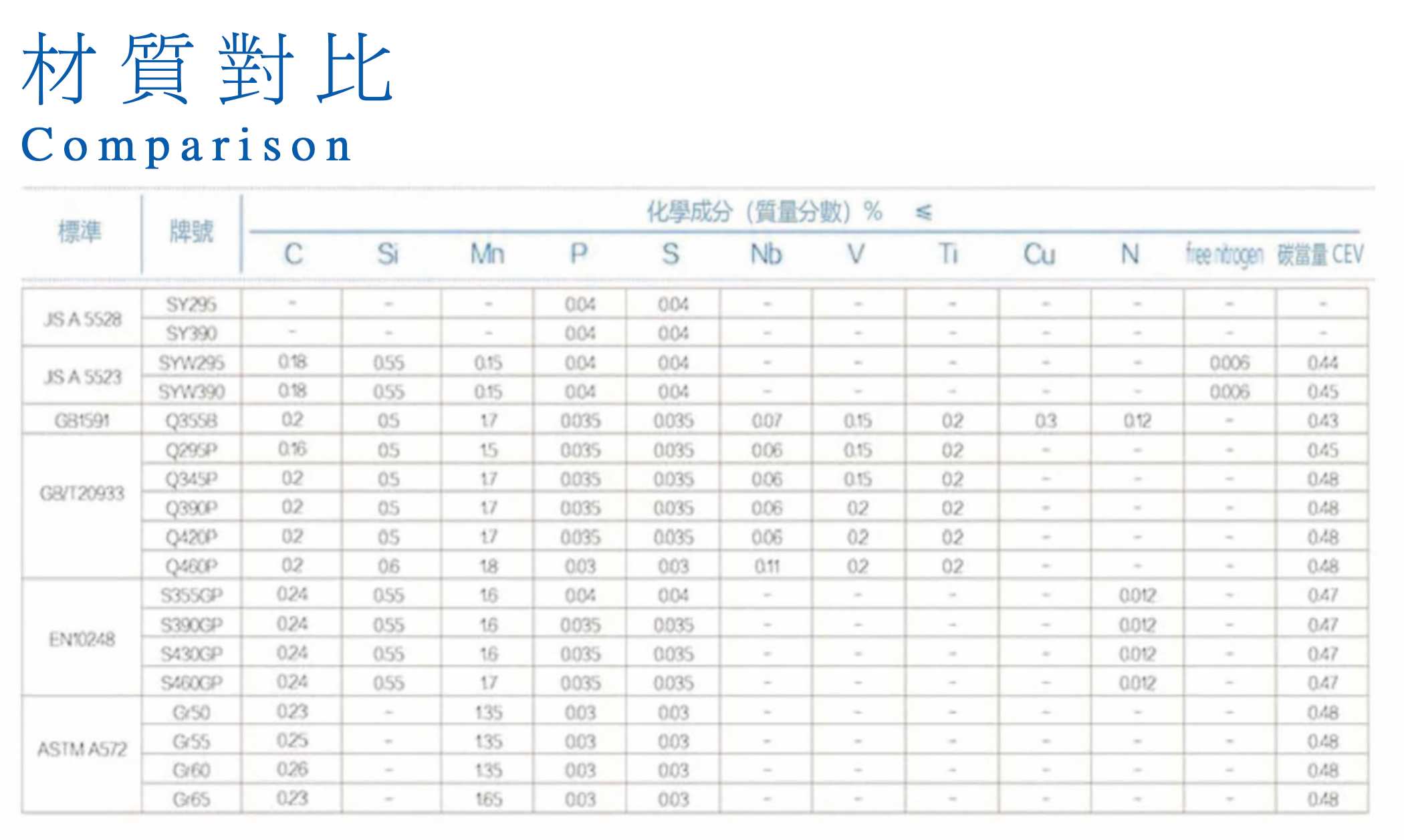

Our company's steel sheet piles are produced using the most advanced basic oxygen furnace (including LF refining) smelting and universal tandem rolling mill technology, completing in one heat. Under a strict quality control system, we manufacture hot-rolled steel sheet piles in compliance with GB/T 20933-2014, JIS A5528/5523, EN10248, and ASTM A328 standards.