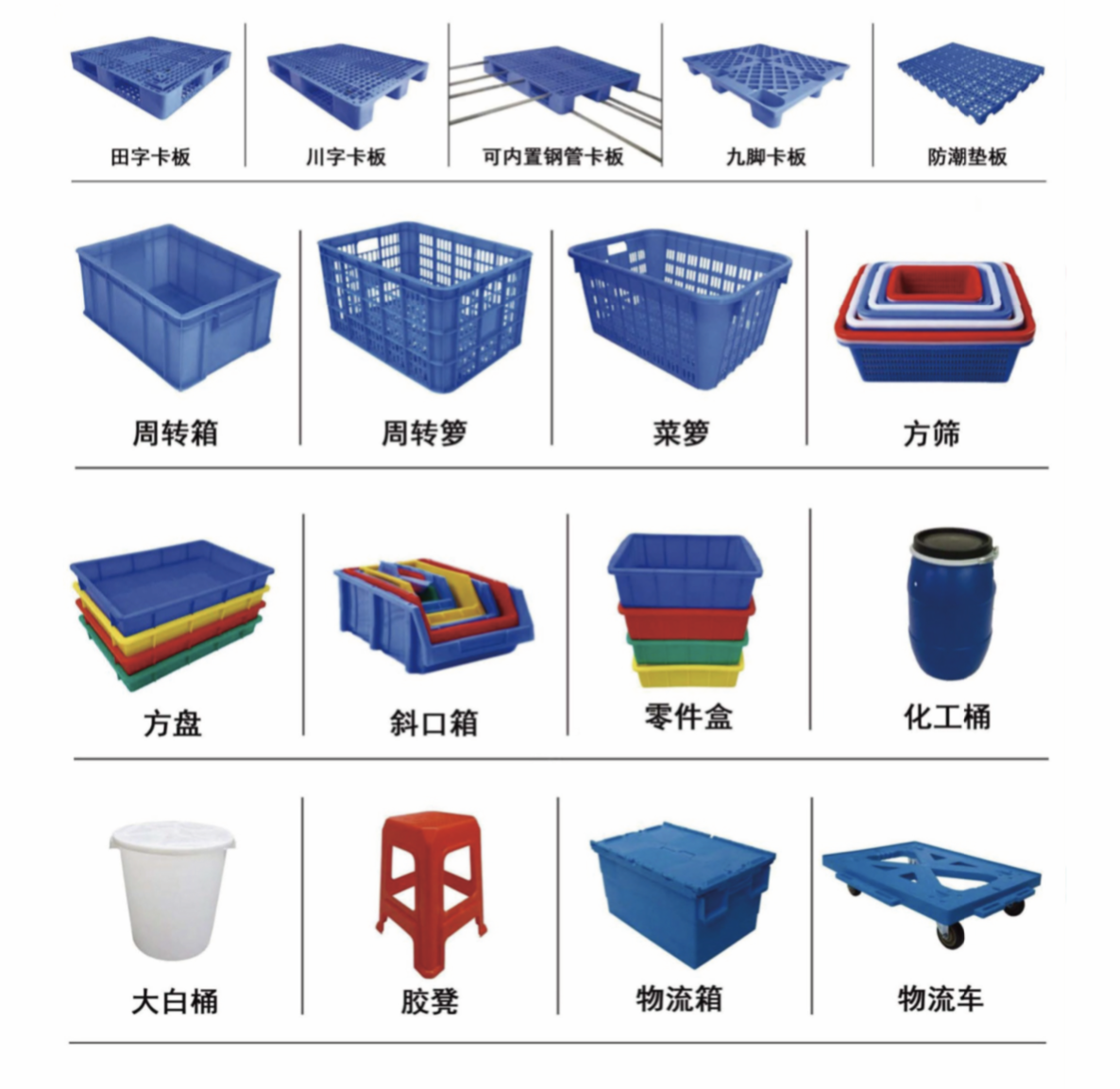

Shelf Pallet Series

Shelf pallets are specialized pallets for warehouse or automated storage systems. These plastic pallets typically require steel pipes inside to enhance their load-bearing capacity, with the number of steel pipes adjusted based on actual load requirements. Shelf pallets generally have a high load capacity, with dynamic loads reaching 1.5T, static loads reaching 6T, and shelf loads up to 0.8-1T, making them suitable for heavy goods. The choice of shelf pallets should depend on the type of shelves used (beam shelves, drive-in racks, gravity racks, robotic shelves, automated warehouses, etc.). Goods on the pallets should be placed stably on the shelf beams, and the pallet length should exceed the external diameter of the shelves by at least 50mm.

Shelf pallets are widely used in industries such as food, tobacco, chemicals, and pharmaceuticals. They come in various forms such as grid stringer type, grid block type, flat stringer type, grid double-sided, and flat double-sided, catering to different user needs.